- Machinist Calculator Crack

- Free Machining Calculator

- Machinist Calculator App

- Machinist Calculator Downloads

Trusted Manufacturing for Tight Tolerances and Tough Materials

Anyone can find all the formulas for determine various, machining speeds, feeds, finishes, sizes, and adjustments, but why bother when Villa Machine has them right here, intuitive and ready to use? Our machinist calculators are 100% JavaScript and HTML. This means that they are fully browser based and don’t rely on any special third-party software to work. They are without ads, or malicious tracking. We personally use these calculators more than anyone else, because we need them nearly every day, and having them here gives us a really easy way to make them accessible to us at all times. It’s especially useful on our smartphones as it’s designed to fit their screens and calculate on input, so there’s no hunting around for extra buttons.

It’s important to note that because of rounding errors these calculators may give results that are a negligble amount off from the exact number, but this shouldn’t affect anything except very small values.

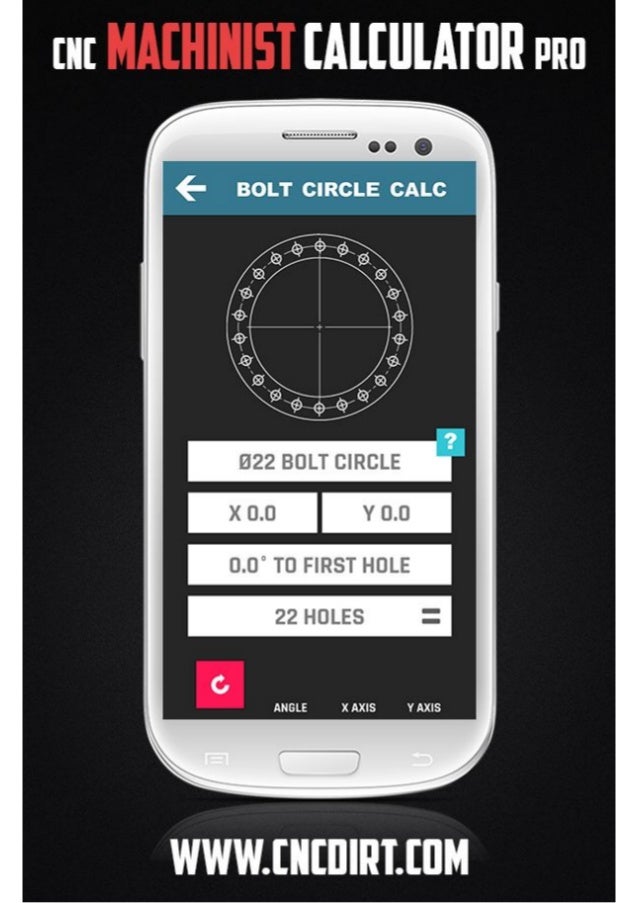

G-Wizard Machinist's Calculator: Calculator. Just your basic engineering calculator, plus a whole lot more! The calculator is tailored to the needs of a machinist. It does trig and unit conversions and should be pretty self-explanatory. Some things to be aware of. Your calculator is great after a few years of using it, I am 100% confident in it. I have used the software daily for probably close to two years now. Anything from aluminum to 17-4 to A2 Rc65 and any tool I throw at it, in any length. The numbers that your calculator give have never failed. The Machinist Calculator has been developed to quickly solve common machine shop trigonometry and math problems at a price every machinist can afford! As a machinist or CNC programmer, you often have to use trigonometry to calculate hole positions, chamfers, sine bar stacks, dovetail measurements, bolt circles, etc.

Villa Machine Associates Inc. assumes no responsibility for the results produced by these calculators. The results are theoretical and are for planning purposes only

Our “Surface Finish” calculator is really our most powerful calculator by far. It’s actually two seperate calculators but most of the time we only use the second one. The first one takes an end mill with a corner radius milling up a slope and outputs the radius of the scallop that it creates. This phenomenon is better explained on the actual web page. This method of machining is very sensitive to runout so if your end mill has more than a few tenths of runout it will be cutting with one tooth the whole time and create a choppy non-uniform finish. The second one is for calculating the surface finish of a normal ball nose end mill. If you used the first calculator you would put the diameter that it gives you and use it as the diameter in the second one. The real beauty of the second one is that if you input a diameter and surface finish, it will inversely calculate the step over for you. On top of that if you were ball milling lengthwise along the inside of a rounded trough or an outer radius the stepover dynamically changes to keep a consistent surface finish. All you need to do is put a value in the radius input and it will tell you the arc length stepover to maintain surface finish. Note that the stepover is measured along the surface and not the toolpath. If you put a 0.5in diameter ball nose endmill inside of a 0.4in radius trough you would use the arc length of the trough’s radius divided by the stepover given to calculate the number of passes to take.

As one can see, in the two pictures below, an end mill with a corner radius on a shallow slope produces much shallower scallops than a ballnose end mill would. This results in a better surface finish and much faster machining time. The “FAKE BALL NOSE DIA CALC” is designed to give you an accurate calculation of the adjusted diameter for calculating surface finish. The “SURFACE FINISH” calculator also includes a stepover adjustment calculator for internal, and external radii. A ballnose end mill makes smaller scallops on an internal radius, and larger scallops on an external radius, and so it must be adjusted to maintain consistent surface finish. Click the pictures for a larger version.

Machinist Calculator Crack

***Villa Machine Associates Inc. assumes no responsibility for the results produced by these calculators. The results are theoretical and are for planning purposes only.

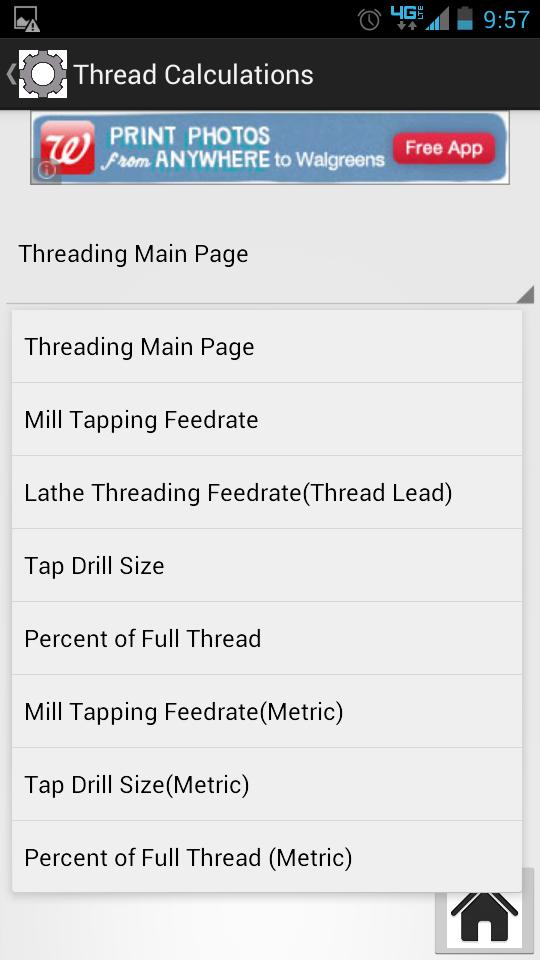

Our two “Tapping” calculators are for figuring out the minor diameters, thread percentages, drilling depths, tapping depths, and fully threaded depths of threaded holes. There are two calculators that operate in tandem with each other, an inch and a metric one. Every related value changes on input, so if for instance you change the thread percentage, then the minor diameter will update, or if you change the fully threaded depth, the tapping and drilling depths will change. The depths in the calculators are based on a “semi-bottoming style” tap with 2~3 lead threads. If possible, it’s best to drill deeper and use a “gun style” tap which has up to 7 lead threads and will prevent tap breakage. Unless there’s a special need we prefer to make our threads approximately 65%, sometimes less if they’re more than two times the tap diameter in depth. The default cut tapping value is 77% as this is the standard on most drill/tap charts, and the default form tapping value is 65%.

The calculators below are designed to help calculate the hole diameters, depths, and percentages for a cutting tap.***

Values are in inches and millimeters.

Free Machining Calculator

Changing the values in the calculator(s) will update other values in both calculators.

***Villa Machine Associates Inc. assumes no responsibility for the results produced by these calculators. The results are theoretical and are for planning purposes only.

Machinist Calculator App

Our two “Tapping” calculators are for figuring out the minor diameters, thread percentages, drilling depths, tapping depths, and fully threaded depths of threaded holes. There are two calculators that operate in tandem with each other, an inch and a metric one. Every related value changes on input, so if for instance you change the thread percentage, then the minor diameter will update, or if you change the fully threaded depth, the tapping and drilling depths will change. The depths in the calculators are based on a “semi-bottoming style” tap with 2~3 lead threads. If possible, it’s best to drill deeper and use a “gun style” tap which has up to 7 lead threads and will prevent tap breakage. Unless there’s a special need we prefer to make our threads approximately 65%, sometimes less if they’re more than two times the tap diameter in depth. The default cut tapping value is 77% as this is the standard on most drill/tap charts, and the default form tapping value is 65%.

The calculators below are designed to help calculate the hole diameters, depths, and percentages for a forming tap.***

Values are in inches and millimeters.

Changing the values in the calculator(s) will update other values in both calculators.

***Villa Machine Associates Inc. assumes no responsibility for the results produced by these calculators. The results are theoretical and are for planning purposes only.

Machinist Calculator Downloads

Our “Countersink” calculator is nothing too fancy but it helps us avoid a lot of confusion. Like the Tapping calculators there are two calculators that operate in tandem, an inch one and a metric one. You put in an angle, a current diameter, and a desired diameter. The output is a Z adjustment that you would put into the tool lengh compensation register on a CNC machining center. If the number is negative then you would add a negative amount to the length compensation and vice versa if it’s positive. If you’re starting with no countersink, do not use the existing hole diameter as the current diameter, use zero as the current diameter and this will estimate the depth required to make the desired countersink assuming the tip of the tool is perfectly pointed (they never are). Whenever we “touch off” a countersink in a machining center, we raise the Z offset to prevent overcutting from possible tool tip error; the tool is run and we use the calculator to adjust the depth.

The calculators below are designed to help calculate Z depth adjustment for a countersink with a given angle.***

Values are in inches and millimeters.

Changing the values in the calculator(s) will update other values in both calculators.

***Villa Machine Associates Inc. assumes no responsibility for the results produced by these calculators. The results are theoretical and are for planning purposes only.

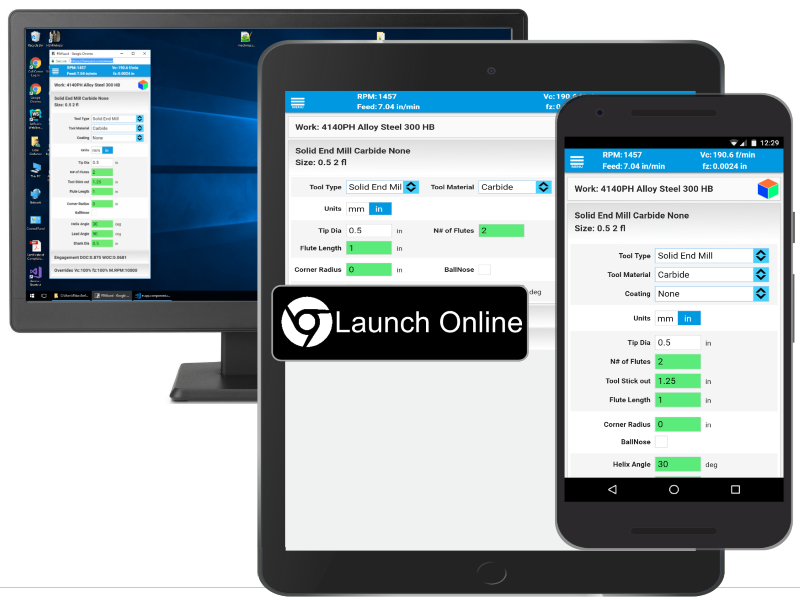

Our “Speeds and Feeds” calculator doesn’t give you recommended feeds and speeds, but it does tell you what RPM and feed rate(s) to run a tool for a given surface speed and feed per tooth. Tooling manufacturers always supply charts with data for surface speeds and feed rates for a given tool diameter. Like the Tapping and Countersink calculators, the Speeds and Feeds one is two tandem calculators, one inch and one metric. There are inputs for surface feet (meters), diameter, RPM, number of teeth, feed per tooth, feed per revolution, and feed per minute. If you change one input the other corresponding inputs change to match the updated information. Let’s say you’re running a 0.4219in drill in steel. The manufacturer might say to go 90sfm (surface feet/minute) and 0.0085in per revolution. Input those numbers and you’ll get 688 rpm at 5.85 inches per minute. Note that the feed per revolution for a drill is usually implied as the total feed per revolution, not per tooth.

The calculators below are designed to help calculate the speeds and feeds in inches and millimeters based on surface feet, surface meters, feed per tooth, diameter, et cetera.***

Values are in inches and millimeters.

Changing the values in the calculator(s) will update other values in both calculators.

***Villa Machine Associates Inc. assumes no responsibility for the results produced by these calculators. The results are theoretical and are for planning purposes only.

IF ANYONE CAN GET IT DONE RIGHT, IT'S

VILLA MACHINE

A machinist’s calculator is a calculator that features many one-button formulas commonly used during the machining process; it is intended for use by machinists and those with similar careers. To cut or form parts, machinists need to calculate feed rate and cutting speed, and a machinist’s calculator can help to calculate them quickly. If a grid of holes needs to be drilled into the part, then this calculator will show machinists how much room must be between each hole. Geometry equations typically come up when machinists are making a part, and this calculator has many basic geometry formulas. Wires are commonly needed with some parts, and this calculator will tell machinists the wire size required for the part.

Among the most common calculations machinists need to make are those determining feed rate and cutting speed. These figures need to be precise or the metal being machined may have an incorrect shape, the size may be wrong or the cutting tools may wear out more quickly. While this calculation can be done on paper, this introduces a greater possibility for human error and usually takes much longer to figure. To get the needed numbers using a machinist's calculator, machinists simply plug some basic information — such as drill size and angle — into the device.

Some parts require a grid of holes, whether for fitting other parts to the grid or to create access for wires. These holes normally need to be uniform and, while it usually is not too difficult for machinists to perform this by hand, the machinist’s calculator speeds the process. Even if the grid is not entirely uniform, most calculators allow machinists to plug in exact positioning information for an accurate grid.

Geometry equations and problems, such as finding the right angle or calculating area, commonly come up when machinists are preparing to machine a part. A machinist’s calculator will usually have a list of one-button formulas for common geometry problems. If there is not a one-button formula, then most of these calculators can perform basic math, so machinists can plug in the numbers like they would with a normal calculator.

After a part is machined, it may need wires for power or other reasons. There are many wire sizes, and choosing the wrong wire can provide inadequate power or the wire may be too thick to properly fit into the part. Based on the part’s teeth size, overall size and other factors, the machinist’s calculator will tell users how thick a wire needs to be to properly fit.